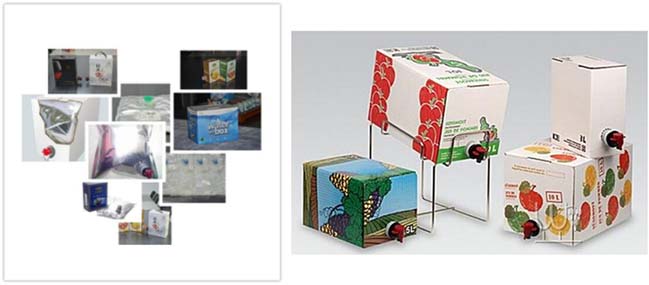

Bag in box is short for BIB , is a kind of container for liquid storage and transportation. It is invented by william ,R. Scholle in 1955 and the fist commercial BIB for the safe transportation and dispensing of liquid.

The bag in box (BIB )consists of a strong bladder (plastic bag) usually made of serveral layers with a cap. The bag is supplied to the ‘filler’ as an empty pre made bag. The ‘filler’ then generally removes the tap, fills the bag and replaces the tap. The bags are available as singles for semi-automatic machines or as web bags, where the bags have perforations between each one. These are used on automated filling systems where the bag is separated on line either before the bag is automatically filled or after. Depending on the end use there are a number of options that can be used on the bag instead of the tap. The bags can be filled from chilled product temperatures up to 90 degrees Celsius.

The bag in box (BIB) has many common commercial applications it is a new recycle package. BIB series filling machine applicable to filling 3-25kg packag of drinking water,wine,fruit juices,concentrates beverages,liquid egg,edible oil, ice cream mix, liquid products,additive. Chemicals,pesticide,liquid fertilizer ,etc

Bag in a box(BIB) is a liquid packaging form that is design flexible , economical and environmentally friendly compared with such traditional ways as glass bottle , PET bottle, plastic drum etc. It has obvious advantages for competition and has fully substituted traditional packages in may fields.

Advantages of BIB :

1. Fresh packaging form

2. Longer shelf life

3. Better photophobism and oxidation resistance

4. Reducing storage and transport cost, improving transport efficicency by over 20%

Post time: Apr-25-2019