In the ever-evolving landscape of industrial production, efficiency and cost-effectiveness are paramount. One of the most innovative solutions to emerge in recent years is the Bag In Box Filling Machine. This advanced piece of equipment has revolutionized the way liquids are packaged, offering a multitude of benefits that significantly reduce production costs. In this article, we will delve into the features and advantages of the Bag In Box Filling Machine, and how it can be a game-changer for your production line.

Compact Structure and Reliability

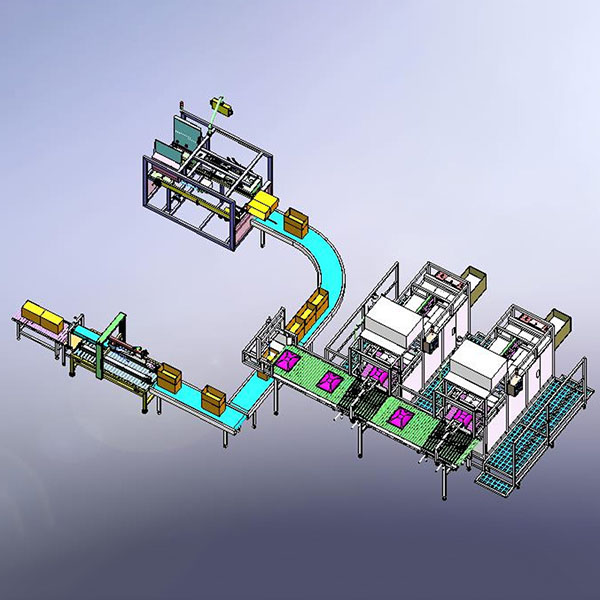

One of the standout features of the Bag In Box Filling Machine is its compact structure. Space is often at a premium in production facilities, and the compact design of this machine ensures that it can be easily integrated into existing production lines without requiring extensive modifications. This not only saves on space but also reduces the initial setup costs.

Moreover, the machine is built using basic device international brand products, which guarantees its reliability and performance. When investing in production equipment, reliability is a critical factor. Downtime due to equipment failure can be costly, both in terms of lost production and repair expenses. The use of internationally recognized brand components ensures that the Bag In Box Filling Machine operates smoothly and consistently, minimizing the risk of unexpected breakdowns.

Advanced Technology to Reduce Dripping

One of the common issues with traditional filling machines is the problem of dripping, which can lead to product wastage and mess. The Bag In Box Filling Machine addresses this issue with new technology that effectively reduces dripping. This not only ensures a cleaner production environment but also minimizes product loss, contributing to overall cost savings.

The advanced technology incorporated into the machine ensures precise filling, reducing the likelihood of overfilling or underfilling. This precision is crucial in maintaining product quality and consistency, which are essential for customer satisfaction and brand reputation.

Cost-Effective Production

The primary advantage of the Bag In Box Filling Machine is its ability to reduce production costs. By minimizing product wastage through its anti-drip technology and ensuring reliable performance with high-quality components, the machine helps to lower operational expenses. Additionally, its compact design reduces the need for extensive modifications to existing production lines, further cutting down on costs.

The machine's efficiency also translates to lower labor costs. With its automated filling process, the need for manual intervention is significantly reduced. This not only speeds up the production process but also allows for better allocation of labor resources, enabling workers to focus on other critical tasks.

Versatility and Adaptability

The Bag In Box Filling Machine is highly versatile and can be used for a wide range of liquid products, including beverages, chemicals, and pharmaceuticals. This adaptability makes it an ideal choice for various industries, allowing companies to streamline their production processes and reduce the need for multiple types of filling equipment.

The machine can be easily adjusted to accommodate different bag sizes and filling volumes, providing flexibility in production. This adaptability ensures that the machine can meet the changing needs of the market, allowing companies to stay competitive and responsive to customer demands.

Environmental Benefits

In addition to its cost-saving advantages, the Bag In Box Filling Machine also offers environmental benefits. The Bag In Box packaging format is more sustainable compared to traditional packaging methods. It uses less plastic and other materials, reducing the overall environmental footprint. This aligns with the growing trend towards sustainability in production and can enhance a company's reputation as an environmentally responsible organization.

Post time: Sep-22-2024