Manufacturing Companies for Spout Machine - BIB200D Bag in Box Multi Heads Filling Machine – Shibo

Manufacturing Companies for Spout Machine - BIB200D Bag in Box Multi Heads Filling Machine – Shibo Detail:

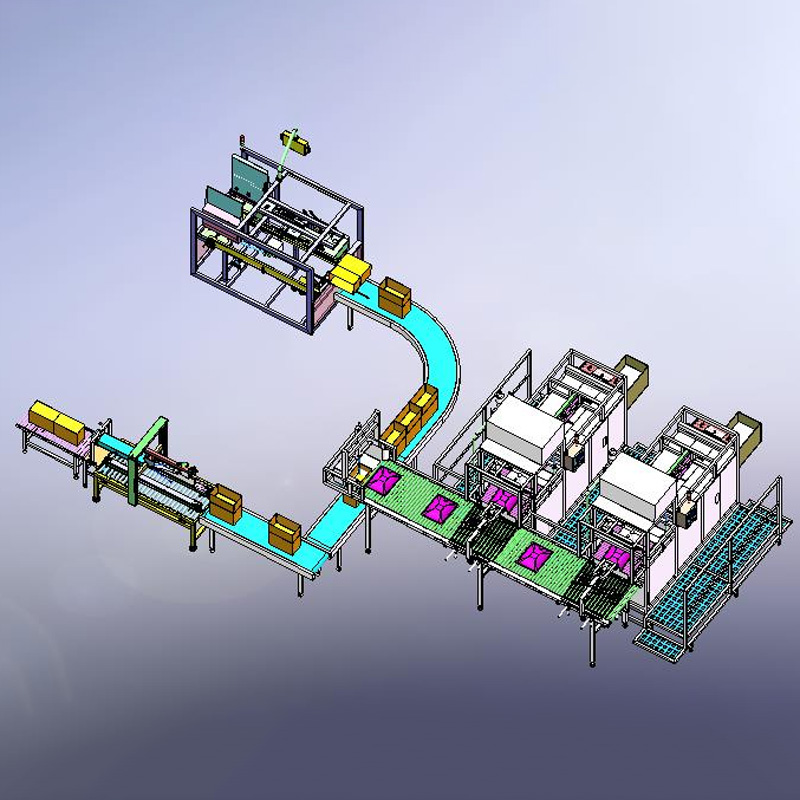

Bag in Box Multi Heads Semi Automatic Filling Machine is always composed of 2 heads, 3heads, 4heads filling machine according to customer filling capacity requirements. Compared with a single head bag in box filling machine, multi heads bags in box filling machine can effectively improve the filling capacity and reduce the product return flow accused repeat sterilization and favor loss.

The bag in box multi heads semi-automatic filling machine was widely used in food and non-food area as follows:

- Tea concentrates

- Diary products (ice mix, cream, milk, condensed milk)

- Fruit products ( Juices, pure, jams, and concentrates)

- Liquid egg products (Whole egg, egg white, and egg yolk)

- Post mix and syrups

- Sauces(mayonnaise, ketchup)

- Water, coffee

- Wine drinks, alcohol, cocktail mix.

- Edible oil /cooking oil

- Pharmacy Fertilizer

Applications

Tea concentrates

Diary products (ice mix , cream , milk , condensed milk)

Fruit products ( Juices, pure, jams, and concentrates)

Liquid egg products (Whole egg, egg white and egg yolk)

Post mix and syrups

Sauces(mayonnaise, ketchup)

Water Bakery products

Soy Wine Edible oil /coking oil

Pharmacy Fertilizer

The Features of BIB200D Bag in Box Multi Heads Filling Machine

can be described as Sanitary, Safe, and Reliable.

1. It can handle products with high viscosity

2. The BIB bag size range from 1L to 25L with a 1-inch spout.

3. The whole equipment is made of stainless steel SUS304, all the surface contacting products are manufactured in stainless steel 316L, other components, such as Rubber, glass, …..are made in sanitary materials approved in food industrial applications, all materials are FDA approved.

4. The machine is designed with safety devices that can protect the operator is accidentally injured by a machine while working.

5. The machine adopts a high-quality Electromagnetic flow-meter or weight system which ensures high filling accuracy over 10 years.

6. It is easy to operate it through Siemens PLC control man-machine interface.

7. Multi languages apply to people from all over the world.

8. High hygiene level by CIP automatic cleaning system

9. Nitrogen supply and vacuuming function are always available

10. The dripping problem can effectively reduce because of new technology

Technical data

Compressed air:6~8bar 30NL/min

Nitrogen supply pressure: Max2.5bar

Filling accuracy: ± 0.5%

Bagging standard:1 inch spout or gland

Filling capacity

5L………… up to 800 bags per hour

10L………… up to 600 bags per hour

20L………… up to 400 bags per hour

Product detail pictures:

Related Product Guide:

Cooperation

We will constantly satisfy our respected customers with our good excellent, superior value and superior assistance due to we're additional experienced and far more hard-working and do it in cost-effective way for Manufacturing Companies for Spout Machine - BIB200D Bag in Box Multi Heads Filling Machine – Shibo , The product will supply to all over the world, such as: Cannes, Germany, Holland, We confirm to public, cooperation, win-win situation as our principle, adhere to the philosophy of make a living by quality, keep developing by honesty , sincerely hope to build up a good relationship with more and more customers and friends, to achieve a win-win situation and common prosperity.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.