Manufacturer for Automatic Drum Filler - ASP200 Bag in Drum Aseptic Filling Machine – Shibo

Manufacturer for Automatic Drum Filler - ASP200 Bag in Drum Aseptic Filling Machine – Shibo Detail:

ASP200 Bag in drum aseptic filling machine is always used for juices, juices pulp, tomato paste, and other liquid products. it can fill 220liters 1 inch spout aseptic drum bag. The characteristic of adopting horizontal filling to effectively solve the phenomenon of condensation water dropping inside the bag.

Features

1. The whole equipment is made of stainless steel SUS304, all the surface contacting products are manufactured in stainless steel 316L, other components, such as Rubber, glass, …..are made in sanitary materials approved in food industrial applications, all materials are FDA approved.

2. The machine is designed with safety devices that can protect the operator is accidentally injured by a machine while working.

3. The machine adopts a high-quality magnetic flow meter or weight system r which ensures high filling accuracy

4. It is easy to operate it through Siemens PLC control man-machine interface.

5. Multi languages apply to people from all over the world.

6. High hygiene level by CIP automatic cleaning system

7. Compact structure, basic device international brand products which ensure the reliability of equipment and working performance

Applications

- Tea concentrates

- Diary products (ice mix , cream , milk , condensed milk)

- Fruit products ( Juices, pure, jams, and concentrates)

- Liquid egg products (Whole egg, egg white and egg yolk)

- Post mix and syrups

- Sauces(mayonnaise, ketchup)

- Water Bakery products

- Soy Wine Edible oil /coking oil

- Pharmacy Fertilizer

Technical Parameter

ASP200(Single head)

Filling capacity: 3~4T/h

Bag standard: 1 inch opening aseptic bag

Encapsulation precision: 0.5Kg

Compressed air:6~8bar 25NL/min

Food steam:6~8bar 50Kg/h

Electric power:3KVA 380V 50HZ

Hydraulic fluctuating

Mass flow meter(E+H)

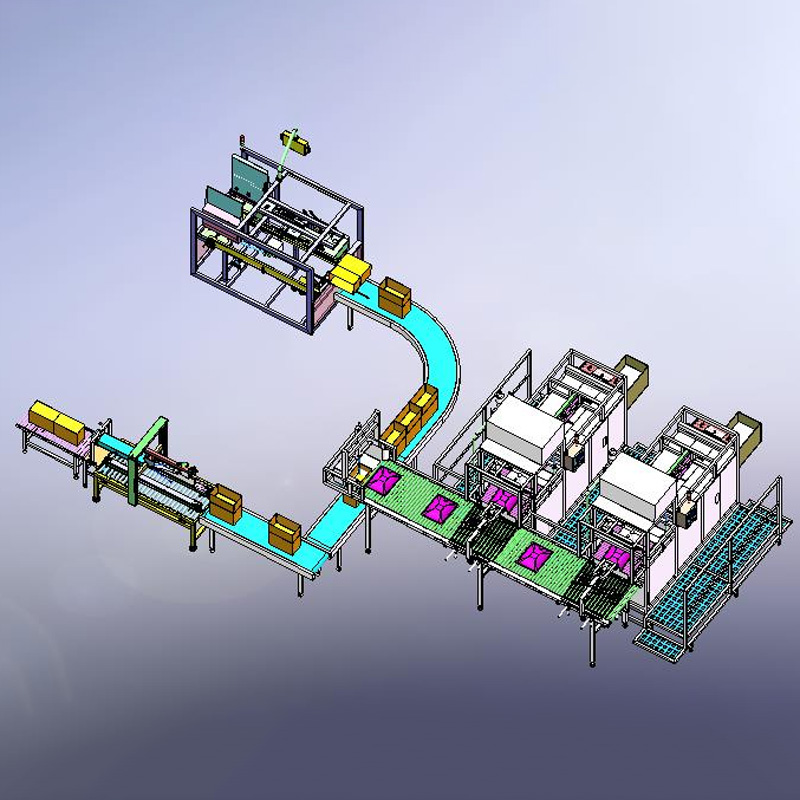

Product detail pictures:

Related Product Guide:

Cooperation

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Manufacturer for Automatic Drum Filler - ASP200 Bag in Drum Aseptic Filling Machine – Shibo , The product will supply to all over the world, such as: azerbaijan, Mecca, Sydney, We rely on high-quality materials, perfect design, excellent customer service and the competitive price to win the trust of many customers at home and abroad. 95%products are exported to overseas markets.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.