Hot-selling Bags & Boxes - ASP100D Double Heads Bag in Box Aseptic Filling Machines – Shibo

Hot-selling Bags & Boxes - ASP100D Double Heads Bag in Box Aseptic Filling Machines – Shibo Detail:

ASP100D double head Bag in Box aseptic filling machines are all used for dairy products, and fruit juices with high-quality requirements. Compared with a single head filling machine, a dual head ASP100D aseptic filling machine is carried out alternatively to avoid the return flow and repeat sterilization which may cause product color and flavor to lose.

ASP100D Double Heads Bag in Box Aseptic Filling Machines widely used in food areas as follows:

- Tea concentrates

- Diary products (ice mix, cream, milk, condensed milk)

- Fruit products ( Juices, pure, jams, and concentrates)

- Sauces(mayonnaise, ketchup)

- Coffee

The Features of ASP100D Double Heads Bag in Box Aseptic Filling Machines can be described as Sanitary, Safe, and Reliable.

1. It can handle products with high viscosity

2. The BIB bag size range from 1L to 25L with a 1-inch spout.

3. The whole equipment is made of stainless steel SUS304, all the surface contacting products are manufactured in stainless steel 316L, other components, such as Rubber, glass, …..are made in sanitary materials approved in food industrial applications, all materials are FDA approved.

4. The machine is designed with safety devices that can protect the operator is accidentally injured by a machine while working.

5. The machine adopts a high-quality Electromagnetic flow meter which ensures high filling accuracy over 10 years.

6. It is easy to operate it through Siemens PLC control man-machine interface.

7. Multi languages apply to people from all over the world.

8. High hygiene level by CIP automatic cleaning system

9. Compact structure, basic device international brand products which ensure the reliability of equipment and working performance

10. The dripping problem can effectively reduce because of new technology

Technical data

Food steam:5~8bar 30kg/h

Filling accuracy:filling volume ± 0.5%

Power: 220V AC 50HZ 1KW

Compressed air: 6-8bar 25NL/min

Bagging standard:1 inch spout

Filling capacity

5L………… up to 380 bags per hour

10L………… up to 320 bags per hour

20L………….up to 250 bags per hour

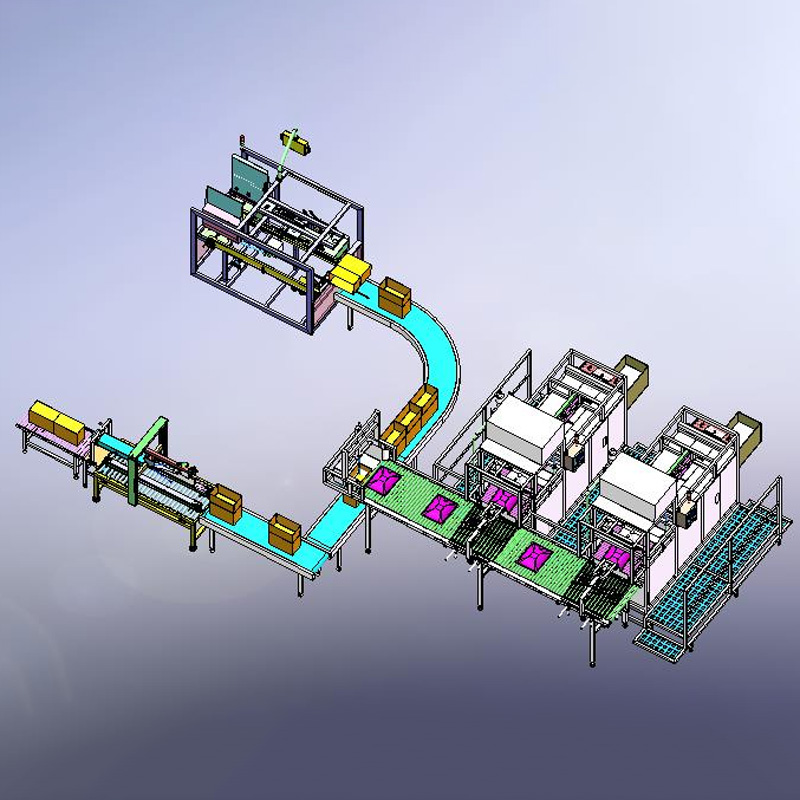

Product detail pictures:

Related Product Guide:

Cooperation

Our enterprise since its inception, often regards solution excellent as enterprise life, continually strengthen output technology, enhance product high quality and continually strengthen organization total high-quality administration, in strict accordance using the national standard ISO 9001:2000 for Hot-selling Bags & Boxes - ASP100D Double Heads Bag in Box Aseptic Filling Machines – Shibo , The product will supply to all over the world, such as: British, Curacao, Turin, We have been persisting in the business essence "Quality First, Honoring Contracts and Standing by Reputations, providing customers with satisfying goods and service. " Friends both at home and abroad are warmly welcome to establish everlasting business relations with us.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.