Factory wholesale Drum Filling Machine - ASP300 Double-Head 1000L liner bag Aseptic Filling Machine – Shibo

Factory wholesale Drum Filling Machine - ASP300 Double-Head 1000L liner bag Aseptic Filling Machine – Shibo Detail:

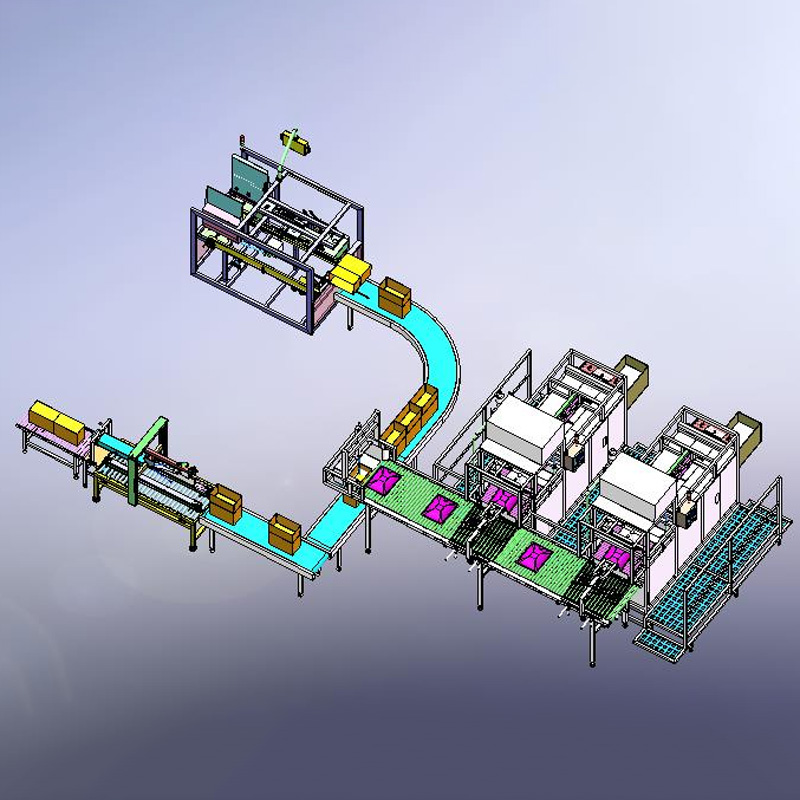

ASP300 double-head 1000L liner bag aseptic filling machine is an aseptic filling equipment used to fill 220 liters and 1000 liters aseptic bags, suitable for products with high requirements such as dairy products, tea,fruit juice, tomato paste and other products.the machine adopt horizontal filling to effectively solve the phenomenon of condensation water drop inside the bag.which caused the mildew spot on the surface of aseptic bags.

Features

The whole equipment is made of stainless steel SUS304, all the surface contacting products are manufactured in stainless steel 316L, other components, such as Rubber, glass, …..are made in sanitary materials approved in food industrial applications, all materials are FDA approved.

The machine is designed with safety devices that can protect the operator is accidentally injured by a machine while working.

The machine adopts a high-quality mass flow meter which ensures high filling accuracy over 10 years.

It is easy to operate it through Siemens PLC control man-machine interface.

Multi-languages apply to people from all over the world.

High hygiene level by CIP automatic cleaning system

Compact structure, basic device international brand products which ensure the reliability of equipment and working performance

ASP300 Single Head Filling Machine :

Filling capacity: 3~6T/h

Bag standard: 1 inch opening aseptic bag

Encapsulation precision: 0.5Kg

Compressed air:6~8bar 18NL/min

Food steam:6~8bar 30Kg/h

Electric power:3KVA 380V 50HZ

Hydraulic fluctuating

Mass flow meter

Optional: Turn plate

ASP300 Double Head Filling Machine :

Filling capacity: 6~15T/h

Bag standard: 1 inch opening aseptic bag

Encapsulation precision: 0.5Kg

Compressed air:6~8bar 25NL/min

Food steam:6~8bar 50Kg/h

Electric power:5KVA 380V 50HZ

Hydraulic fluctuating

Mass flow meter

Optional: Turn plate

Product detail pictures:

Related Product Guide:

Cooperation

Fast and great quotations, informed advisers to help you choose the correct product that suits all your preferences, a short creation time, responsible top quality control and different services for paying and shipping affairs for Factory wholesale Drum Filling Machine - ASP300 Double-Head 1000L liner bag Aseptic Filling Machine – Shibo , The product will supply to all over the world, such as: Pakistan, Nepal, Belgium, Our R&D department always designs with new fashion ideas so we could introduce up-to-date fashion styles every month. Our strict production management systems always ensure stable and high quality products. Our trade team provides timely and efficient services. If there are any interest and inquiry about our products, please contact us in time. We would like to establish a business relationship with your honored company.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.